Globally recognized standards at every stage

Ballistic Testing

Modeling & Simulation

Material Characterization

We possess the capability for high strain rate mechanical testing. Utilizing the cutting-edge Split Hopkinson Pressure Bar, we can investigate the properties of a variety of materials like ceramics, metals, and composites under severe conditions, enabling efficient simulations.

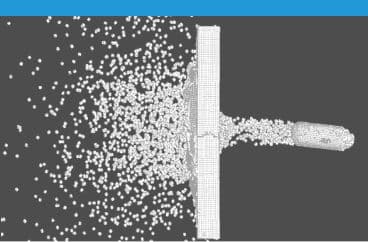

Terminal Ballistics & Impact Analysis

Our numerical modelling of terminal ballistics studies high-speed projectile impact, crucial for the design of defense mechanisms, and forecasting system behavior under various conditions.

Blast Analysis

We perform simulations to study the effects of explosions on structures, which is key to designing secure strutural systems.

Production Process Simulations, Powder Compaction, Sintering/Thermal Analysis, Metal Forming

Our computational methods optimize the performance of manufacturing processes, study the behavior of powders under pressure, and analyze the effects of heat on materials. This aids in creating reliable production processes and improving the properties of end products.

Design, Shape/Topology Optimizations, Sensitivity and Robustness Analysis

We utilize advanced optimization algorithms to identify the ideal design parameters that meet performance requirements. It helps us design more effective systems, assess potential risks, and vulnerabilities, and improve a design's sustainability.