Strength Against Wear in Mining

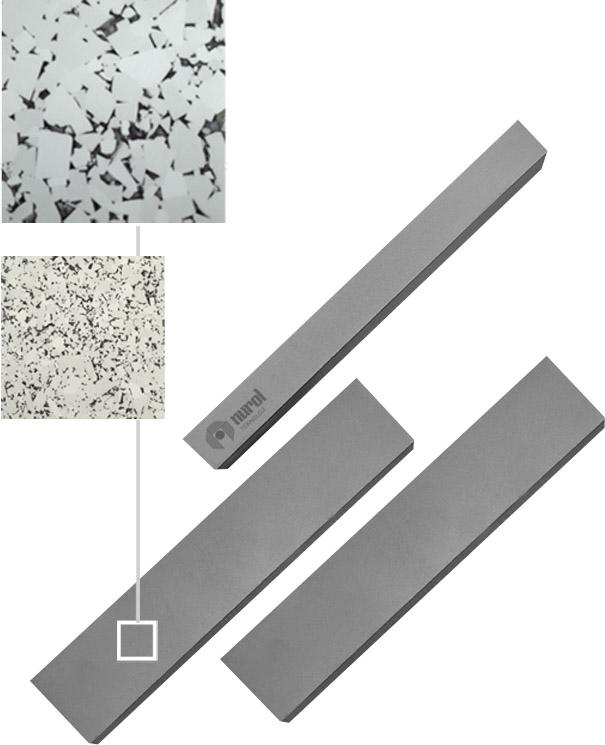

Rotor crusher tips, used in vertical shaft crushers, are among the most critical components operating under high impact and abrasion loads.

Nurol Teknoloji manufactures rotor crusher tips in various sizes and hardness levels using tungsten carbide–based materials. This special material combination ensures high performance and long lifespan in crushing and screening plants while minimizing maintenance requirements.

Key Advantages

- High wear resistance and hardness

- Production flexibility in different geometries and sizes

- Long service life suitable for demanding mining and construction conditions

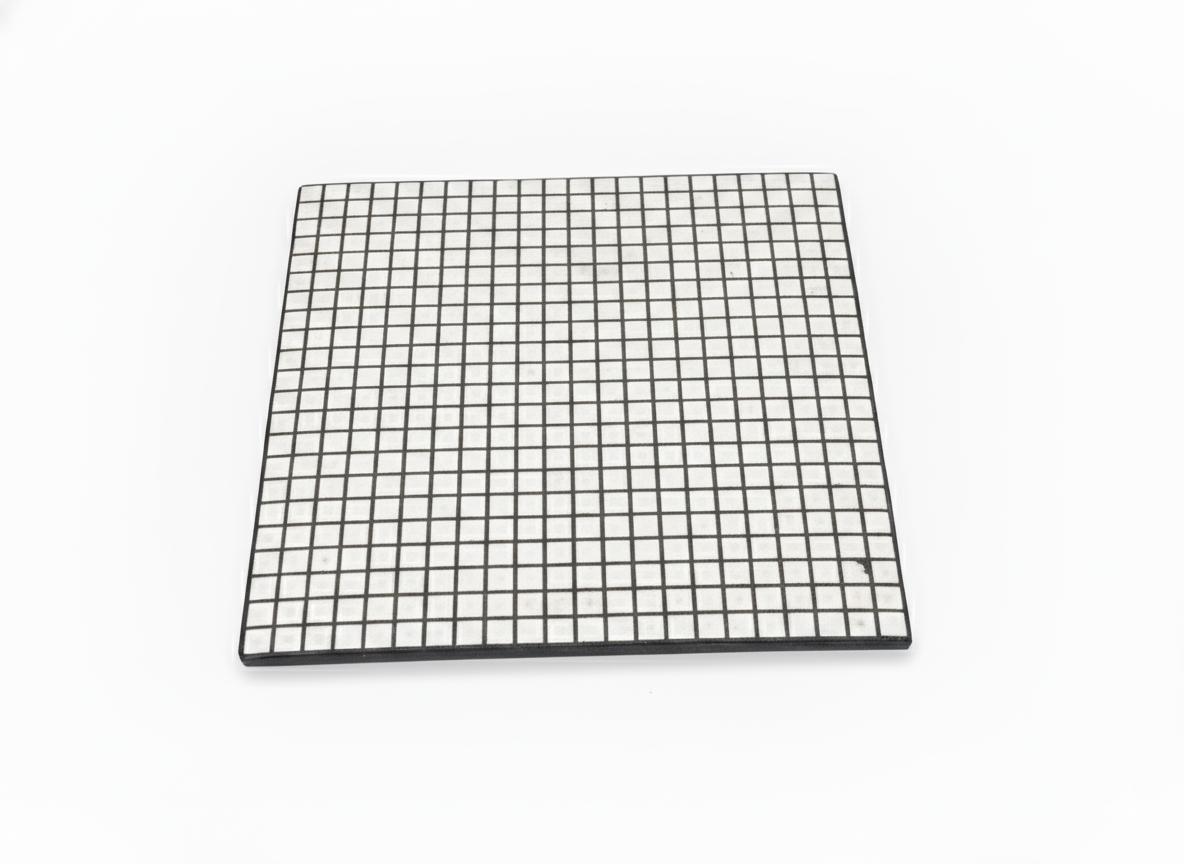

Developed to reduce abrasion and erosion loads encountered in heavy-duty crushing, grinding, and conveying systems.

The wear plates produced by Nurol Teknoloji are reinforced with high-hardness ceramic layers and can be applied to various substrate materials. They are widely used in cement plants, mining and excavation industries, glass and MDF production facilities, and thermal power plants.

Key Advantages

- Structure resistant to extreme abrasion and impact conditions

- Wide range of sizes and thicknesses

- Extended service life that lowers maintenance costs